Hot plate electric roof shakers are equipment used in chemistry and biology laboratories to prepare mixtures or solutions. It consists of a rod resistant to heat and cold, which by means of an electric motor that is manipulated by the operator in the laboratory, allows substances generated by the magnetic field to be mixed to automatically achieve solvents and solutes.

The shaking mechanism must be immersed at least 1.5 times its diameter and positioned safely, and for when the equipment is running, it is necessary that the propeller rotate correctly and is supervised by an expert. The device works with the right speed, especially for the preparation of concentrated solutions, such as: syrups, brines and emulsions; where the flow currents that start from it, are stirred in a certain direction, showing that the blades of the propeller fragment and vigorously friction the liquids.

Hot Plate Electric Roof Shaker Operation

Initially, in order for the agitator to fulfill its functions, it should be taken into account that the equipment is in perfect condition and the user within the laboratory should check that the connections match the appropriate power grid, also the switches should be in the off position. In addition, the speed control is set to 0, so that the stem can be inserted in the center of the container with the substances, until it covers the bottom of the container, without touching the walls of the container and the bottom.

During agitation, the user should turn on the equipment, adjust the speed from the lowest levels, and gradually increase to the appropriate speed. Also, in the shaking process, the glass should be moved with the liquids. Once the practice is finished, the speed is slowed down little by little and the button is turned off.

The stirrer mechanism is applied in multiple laboratory processes, whose objective may be:

- Solid particle arrest.

- Binding of various substances.

- Mixture of solid substances.

- Heat Transfer.

Finally, after use the equipment must be kept clean, removing the container and washing it with abundant hot water and liquid soap, rubbing with gentle movements to reach the entire surface of the vessel. Then, dry it and place it in a safe place.

Agitation Techniques

Through processes that deal with the reproduction of several substances mechanically, order schemes arise depending on the type of samples, since these contain different properties, and agitation will allow to obtain substances that can subsequently be separated.

In this sense, the techniques that apply this technology, allows the union of ingredients to produce homogeneous and pure mixtures. The objective is to develop products or substances, taking into account time, energy and observation, to achieve optimal results.

The importance of agitation techniques allows the implementation of these equipment to be optimized in chemical and biological laboratories, allowing the functional speeds ensure a high quality model to achieve final products, in addition to the technological contribution offered by electric roof agitators, is growing and converting these machines into ideal equipment in all industrial sectors.

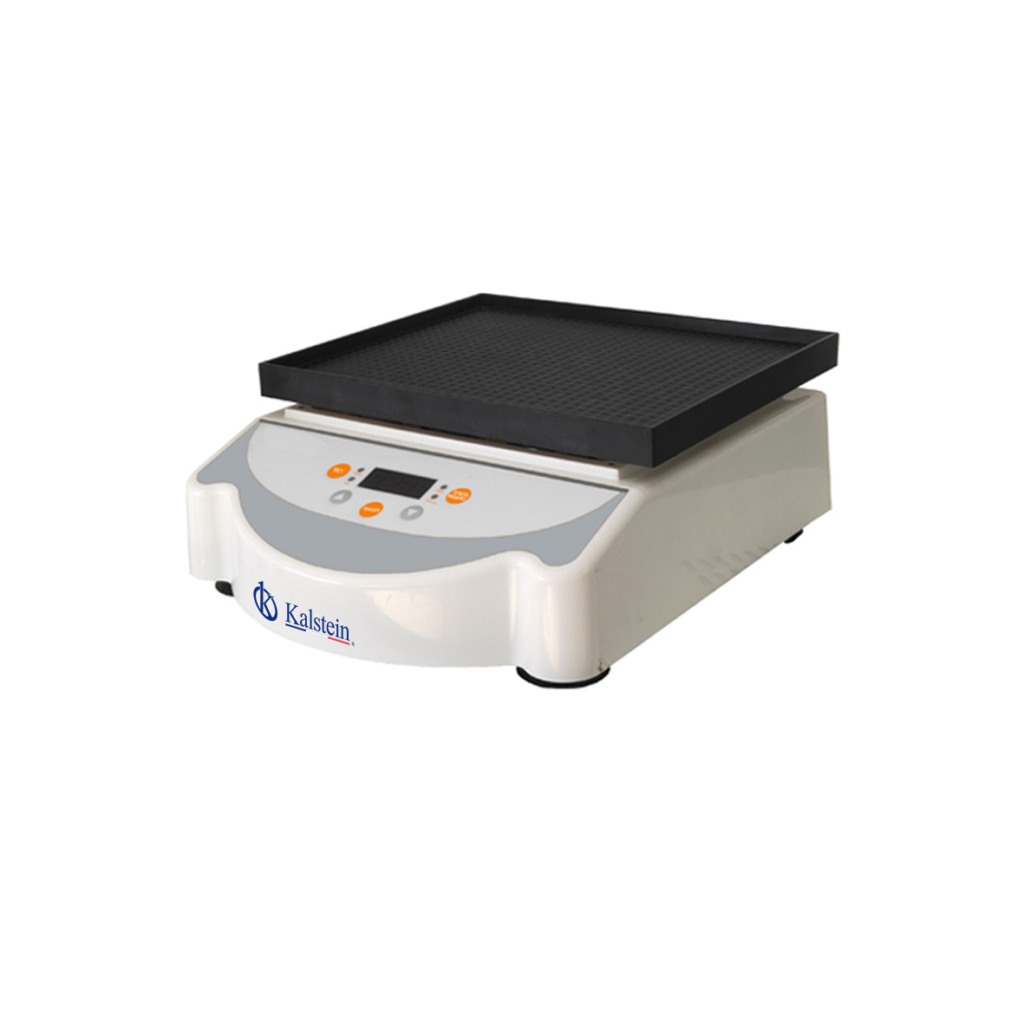

Electric Roof Agitator Hot Plate Brand Kalstein

At Kalstein, we are manufacturers of Hot Plate Electric Roof Shakers and are committed to providing you with the best equipment, with the best technology for our users to operate the best devices internationally. Our equipment belongs to the YR series, and has a compact and simple to operate, it also has a digital display of temperature and speed, allowing to show the heating temperatures of Rt-380 degrees, with a speed of 100-1800 RPM. They are made with a heat- and corrosion-resistant aluminum alloy housing for durability. Our ceramic coated aluminum heating plate is ideal for excellent heat distribution and corrosion resistance.

For more information, you can review our catalog HERE