Laboratory Muffle

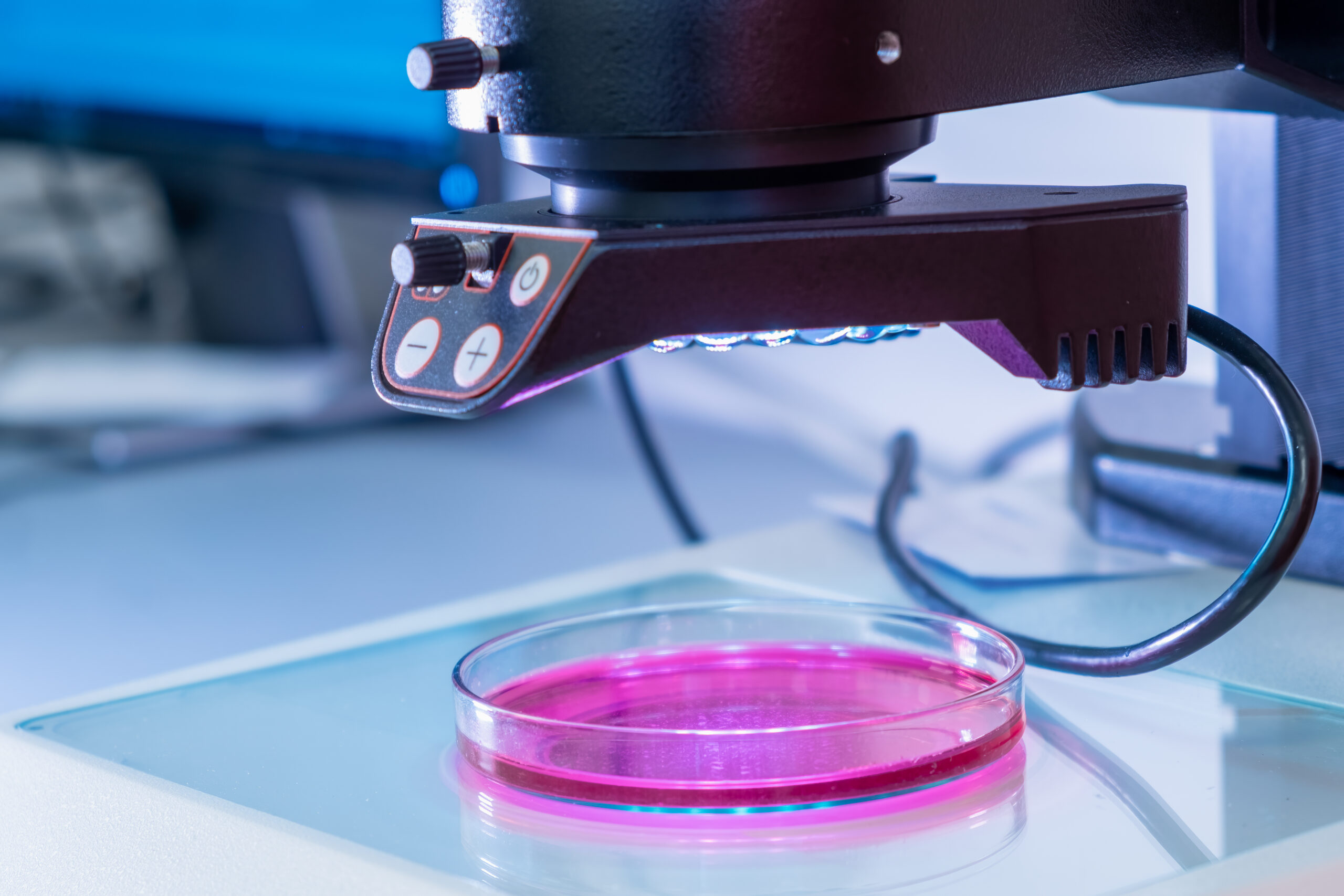

Muffles are used in a variety of laboratories, such as those in the field of materials science. They are also used in industrial settings, such as metal production and typically for high temperature applications. There are several safety considerations to keep in mind when using a muffle furnace. The temperatures reached in a muffle furnace can be very high, and the material being heated can give off hazardous vapors and it is important to have adequate ventilation when using a muffle furnace. Muffle furnaces can be dangerous if not used properly. It is important to follow the manufacturer’s instructions when using a muffle furnace. Improper use of a muffle furnace can cause irreparable damage..

LABORATORY MUFFLES KALSTEIN

At Kalstein you can find the ideal Muffle for Your Laboratory

Universal Lab High Temp Box Muffle Furnace YR05272 // YR05284

YR series muffle furnace adopts box type structure, is more convenient to put and take material, and the max. temperature of the furnace can...

Laboratory Muffle Furnace YR05284-1

Furnace Structure & Chamber: High purity fibrous alumina insulation for maximum energy saving 60-80% less power consumption than other...

Our Laboratory Muffle best seller

Furnace Structure & Chamber:

High purity fibrous alumina insulation for maximum energy saving 60-80% less power consumption than other old style. Heavy duty double layer structure with cooling fan to keep furnace exteriorssafe to touch.

| Model | YR05284-1 |

| Rated voltage | AC 380V 3 phase or 1 phase 50/60Hz |

| Power | 18kw |

| Chamber size | 400x400x400mm, 64L |

| Max. Temperature | 1700 °C |

| Continuous working temperature | 1600 °C |

| Max. Heating Rate | 30 °C /min; Suggest to use 10°C/min under 1400°C, 1400°C-1600°C 5°C/min, >1600°C 2°C/min; |

| Temperature controller | PID automatic control and auto-tune function. 30programmable segments for precise control. Built in protection for over-heatingand broken thermocouple |

| Temperature Accuracy | +/- 1°C |

| Heating Element | MoSi2 heater |

| Thermocouple | B type |

| Standard parts | Reserve heater 2pcs, crucible tongs 1pc, asbestos gloves 1pair , one user manual |

Analysis of the best Muffle for Your Laboratory

Why is a Muffle important in a Chemistry Laboratory?

There are several wonderful instruments and equipment, such as the studies that are carried out in them. There is every prototype and with many benefits, which are used according...

How do you keep Muffles in the Lab?

A muffle is a laboratory furnace used for calcination, melting and other heat treatment that requires high temperatures. They are constructed with a porcelain or cast metal chamber...

How are muffles used in sample analysis?

The muffle is a laboratory furnace designed to carry out laboratory procedures that require uniform exposure of high temperatures. This type of furnace consists of a closed chamber...

How many types of muffles are there?

Muffles are versatile units capable of incinerating materials and melting metals, through thermal energy. They are used within laboratories, for the calcination of substances...

Catalog of models of Muffle on offer

Universal Lab High Temp Box Muffle Furnace YR05272 // YR05284

Select options

Laboratory Muffle Furnace YR05284-1

Add to cart

Controlled Atmosphere Muffle Furnace YR06618// YR06621

Select options

Four à moufle à atmosphère contrôlée YR06618// YR06621

Select options

Muffle Furnace YR06648

Add to cart

Four à Moufle YR06648

Add to cart

Four à Atmosphère Contrôlée YR06668

Add to cart

Atmosphere Furnace YR06668

Add to cart

KALSTEIN UPDATED

Guidelines for you to become an expert in Muffle

The Muffle equipment are essential products in Your Laboratory, we provide you with guidance and recommendations for a better use, so you can work like an expert.

Muffles in which type of laboratory are used?

Muffle is a equipment used for high temperature tests for various purposes, such…

How are Muffles stored in the Laboratory?

Muffles are used in a variety of laboratories, such as those in the field of materials science…

How are muffles used in the manufacture of chemicals?

The muffle is an instrument used for the smelting of metals and for the cooking of materials…

Laboratory Muffle Furnaces: When are they used?

Muffle furnaces are used as a laboratory instrument to dry and sterilize glass and metal containers from high temperatures for various purposes, such as heat treatment, calcination tests, incineration of organic and inorganic samples and cooking of ceramic materials, among others…

Frequently asked questions from our customers about Muffle

To know the price of the muffle we invite you to send us an email with your request using the contact form. HERE

The delivery time of your Kalstein product will depend on the following:

- Whether the equipment you are interested in is in stock or if it needs to be manufactured.

- The type of freight you have chosen, which can be either air or sea.

- Equipment in stock:

– Delivery Time (Air): 15-30 days.

– Delivery Time (Sea): 45-60 days.

- Equipment not in stock:

– Delivery Time (Air): 30-60 days.

– Delivery Time (Sea): 60-90 days.

You can make your purchase through:

- By email: [email protected]

- By phone: +33 (0) 1 70 39 26 50

- Online shopping: Through the official Kalstein website in your country.

All Kalstein equipment comes with a 1-year warranty against manufacturing defects. The warranty does not cover damages caused by improper installation or operation by the user, transportation defects, or uses other than those specified by the manufacturer. The warranty excludes electrical parts or consumables. For more information, visit our terms and conditions by clicking HERE.

At Kalstein, we provide our customers with inductions and technical support through new online methods. You can visit our induction videos, technical assistance, and guidance provided by a Kalstein team through our Youtube channel (Kalstein English). HERE

Certainly, you can request a quote for the Kalstein equipment you’re interested in, directly from our official website. Once you have identified the model of your preference, click HERE

Send us a direct message and one of our agents will contact you

Muffle

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed dignissim placerat mauris cursus laoreet. Nam feugiat lacus ex, at fermentum sapien accumsan nec. Curabitur auctor porttitor mi non malesuada. Aenean condimentum, purus vitae rhoncus imperdiet, justo eros aliquam ipsum, at egestas leo diam eget libero.

Catalog of models of Muffle on offer.

-

Unité d’aspiration YR06946

-

Appareil de radiographie vétérinaire numérique portable YR06945

-

Autoclave à vapeur sous pression de type vertical avec écran LCD YR06941 // YR06944

This product has multiple variants. The options may be chosen on the product page -

Autoclave de table à vide pulsé de classe B, 85 L, YR06925

-

Vertical type pressure steam autoclave with LCD display YR06941 // YR06944

This product has multiple variants. The options may be chosen on the product page -

85Lt Class B Pulsating Vacuum Benchtop Autoclave YR06925

-

YR06931 // YR06940 Forced Air Electric Drying Oven

This product has multiple variants. The options may be chosen on the product page -

Suction Unit YR06946

-

Portable Digital Veterinary X-ray YR06945

-

YR06828 Class B benchtop pulsating vacuum autoclave

-

Benchtop autoclave with pulsating vacuum, class B, with LCD display YR06926 // YR06930

This product has multiple variants. The options may be chosen on the product page -

Machine de traitement d’eau pure pour dialyse 500 L/h et 1000 L/h YR06922-YR06923

This product has multiple variants. The options may be chosen on the product page -

Défibrillateur externe automatisé YR06924

-

Automatic External Defibrillator YR06924

-

Moniteur ECG YR06920 – YR06921

This product has multiple variants. The options may be chosen on the product page -

ECG Monitor YR06920 – YR06921

This product has multiple variants. The options may be chosen on the product page

Descubre más de nuestro catálogo

Tipos de Muffle

[Producto] A

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

[Producto] B

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Find out more about Muffle with our guides.

Unveiling the Secrets: Veterinary Coagulation Analyzer – The High-Tech Innovation in Veterinary Health

Explore the ins and outs of the Veterinary Coagulation Analyzer by Kalstein. Discover why it's the go-to choice for professionals...

Exploring the Versatile World of Kalstein Ultrasound Scanners

Discover the unparalleled versatility and capabilities of Kalstein's Ultrasound Scanners, a benchmark in medical imaging technology.

Exploring Kalstein’s Laminar Flow Hoods, Clean Benches, and Biosecurity Cabinets: Safety and Efficiency in the Laboratory

Discover the excellence of Kalstein’s laminar flow hoods, clean benches, and biosecurity cabinets, ensuring safety and efficiency in laboratory settings.