Ovens

Ovens are essential equipment for drying, sterilization, and heat treatment across various industrial and laboratory sectors. They allow precise control of temperature and humidity, ensuring perfect uniformity throughout the process. Their use is crucial to guarantee the quality and reliability of analyses or productions, especially in pharmaceutical, medical, and veterinary fields. We offer a range tailored to meet the strictest requirements, combining performance, robustness, and ease of use.

Among the different types of ovens, vacuum ovens and industrial ovens hold a major place. Vacuum ovens allow working under low pressure to prevent oxidation or thermal alterations, ideal for sensitive applications. Industrial ovens, meanwhile, are designed for intensive cycles with large capacity, providing efficient solutions for mass treatment and demanding environments. We guarantee a wide selection of devices adapted to each specific need.

Types of ovens your laboratory might need

Vacuum Ovens

Vacuum ovens provide a controlled low-pressure environment, which reduces boiling points and prevents oxidation of sensitive samples. They are particularly used in research laboratories, pharmaceuticals, and the electronics industry for delicate drying of materials. Thanks to advanced technology, they ensure stable and repeatable conditions for reliable results.

Kalstein offers vacuum ovens with various capacities and features, including integrated vacuum systems and precise temperature controllers. These devices facilitate sample preparation for advanced analyses while protecting their integrity. They are designed for intuitive use and simplified maintenance, adapted to modern laboratory requirements.

Industrial Oven

Industrial ovens are designed to withstand continuous cycles and heavy loads, meeting the demands of mass production and the challenging conditions of industrial environments. They enable homogeneous heat treatments on large quantities of products, thus guaranteeing process compliance and quality.

Our Kalstein industrial ovens feature robust structures, high-performance thermal insulation, and advanced control systems to ensure optimal energy efficiency. Suitable for various sectors, they offer flexibility in programming and can be configured according to client specifications for maximum output.

What should you know before choosing an oven and making an investment?

Key Factors to Consider

Choosing an oven requires studying several key factors including the accuracy of temperature control, useful capacity, and quality of thermal insulation. These criteria ensure efficient and safe operation. The reliability of electronic components and ease of maintenance are also crucial for lasting use in professional settings.

Additionally, it is essential to consider the oven’s compatibility with the substances to be processed, particularly regarding the chemical resistance of internal materials. Safety and ease of use via intuitive interfaces also impact productivity. Finally, the technical support and after-sales service provided by the manufacturer should be part of the decision.

Price Range on the Market

The oven market features a wide price range depending on performance, capacity, and specific functionalities. There are entry-level models accessible for basic needs and high-end ovens for demanding applications. The choice should be made based on usage objectives while respecting the available budget.

It is important to note that costs may vary depending on customized options, such as digital controls, integrated vacuum systems, or additional accessories. Maintenance and energy expenses should also be considered to calculate the total cost of ownership over the device’s lifespan.

Value for Money

The balance between quality and price is fundamental to ensure a profitable investment. Choosing a durable, reliable, and high-performing oven, even if initially more expensive, reduces costs related to breakdowns, frequent interventions, and premature replacements. Kalstein offers products combining robustness and innovation with this in mind.

Our ovens are designed to offer excellent value for money by integrating the latest technological innovations and ensuring long durability. This guarantees an optimal return on investment especially in demanding environments where reliability is essential for operational continuity.

Lifespan Based on Usage and Maintenance

The lifespan of ovens largely depends on frequency of use, regular maintenance, and quality of materials used. Proper maintenance significantly extends performance and equipment safety. Kalstein advises rigorous monitoring including checking seals, probes, and cleaning internal surfaces.

We recommend strictly following the usage and maintenance instructions provided with each device to optimize its lifespan. Moreover, our technical support and assistance services ensure rapid intervention if needed, thus guaranteeing uninterrupted operational continuity for your activities.

KALSTEIN OVENS

Among so many products, at Kalstein you will find the ideal oven for your clinic

If you don’t know which oven to buy, our Kalstein team is here to advise and guide you to the model best suited to your specific needs, taking into account your technical and budgetary criteria for a smart and lasting investment.

Double Door Industrial Air Drying Oven YR05257-1 (A) // YR05259-1 (SS)

The Double Door Industrial Air Drying Oven YR05257-1 (A) // YR05259-1 (SS) offers cutting-edge technology for efficient…

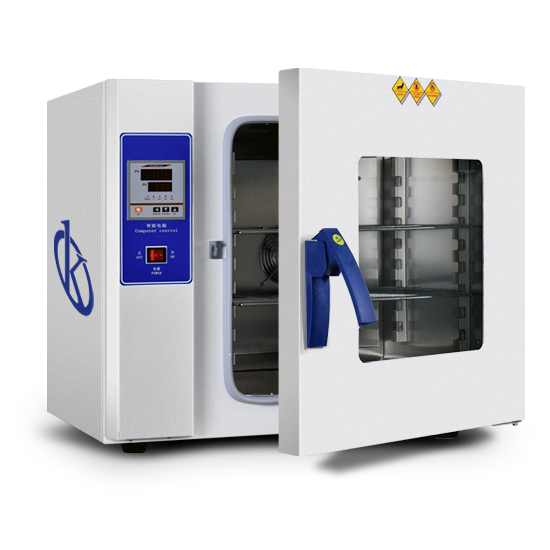

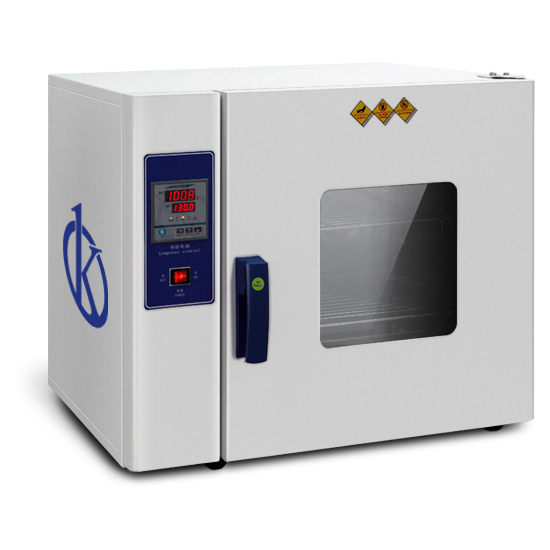

Single Door Industrial Air Drying Oven YR05256 // YR05258

The Single Door Industrial Air Drying Oven YR05256 // YR05258 stands out for its microcomputer intelligent temperature c…

YR06931 // YR06940 Forced Air Electric Drying Oven

The YR06931/YR06940 Forced Air Electric Drying Oven is the ideal solution for drying processes in various industrial, sc…

Four de séchage sous vide YR06623 // YR06626

Le four de séchage sous vide YR06623 // YR06626 est un équipement de laboratoire conçu pour les processus de séchage, de…

Our best-selling oven

The Double Door Industrial Air Drying Oven YR05257-1 (A) // YR05259-1 (SS) offers cutting-edge technology for efficient dehydration and drying. Its dual-layer door, paired with an intelligent microcomputer temperature control and digital display, ensures precision and reliability. Equipped with a centrifugal turbine, it provides uniform heat distribution, making it perfect for continuous operation in sectors such as mining and production workshops. Moreover, this oven is extensively used in industries like electroplating, electronics, food and plastic manufacturing, leather, and hardware.

The price of industrial air drying ovens can vary significantly based on features and specifications. For a high-quality model like the YR05257-1 (A) // YR05259-1 (SS), you can expect a market range typically from $3,000 to $6,000, depending on the configuration and additional elements included. To receive a precise quote, we invite you to set up an automatic quotation through the Kalstein Plus platform.

| Model | YR05257-1 (A) | YR05259-1 (SS) |

| Power Supply Voltage | 380 | |

| Temperature Range (℃) | RT+5~250 | |

| Timer Range | 0~999 h | |

| Temperature Accuracy | ±1 | |

| Temperature Fluctuation (%) | ±2 | |

| Chamber Material | Zinc | Stainless Steel |

| Liters | 864 | |

| Power (KW) | 8~12 | |

| Interior Size (mm) (Height × Width × Depth) | 1200×900×800 | |

| External Size (mm) (Height × Width × Depth) | 2000×1450×1000 | |

| Net Weight (KG) | 214 | |

| Shipping Weight (KG) | 221 | |

Needs analysis for choosing the right oven.

Maximizing Efficiency with Kalstein Vacuum Ovens: Features, Comparisons, and User Insights

When it comes to precision and reliability in laboratory equipment, few brands stand out like Kalstein. Their vacuum ovens have gained a well-deserved reputatio…

Maximize Thermal Efficiency in Your Laboratory with State-of-the-Art Ovens

Choosing the right equipment for your laboratory is essential, and ovens play a fundamental role in ensuring precision and control in processes that require con…

Ovens: dry heat sterilization

Hot air is one of the most widely used dry heat sterilization methods. This process is carried out in ovens, which allow uniform heat distribution inside, where…

Benefits of Industrial Ovens for Cosmiatry

Industrial ovens are equipment in charge of producing large amounts of heat, allowing to operate with various materials and samples. In addition, their size all…

Ovens on special offers

YR06931 // YR06940 Forced Air Electric Drying Oven

Four de séchage sous vide YR06623 // YR06626

Vacuum Drying Oven YR06623 // YR06626

Four de Séchage Thermostatique Programmable YR06444 -YR06445

Programmable Thermostatic Drying Oven YR06444 -YR06445

Electric Heating Drying Oven YR06446

Electric heating drying oven YR05244 // YR05247

Electric heating drying oven YR05248 // YR05255

Kalstein constantly updates its ovens with the latest technologies.

Comprehensive guides to select and use the oven according to your precise requirements.

Arrangements, guides, and recommendations to work like an expert with our ovens, optimizing every cycle, ensuring regular maintenance, and maximizing the device’s lifespan.

Laboratory ovens and muffles: What are the differences and applications?

It is essential equipment in laboratories and is also known as drying oven; is used for drying and sterilizing glass and metal containers; now, the mu…

What are the differences between Drying Ovens, Muffle Ovens and Laboratory Incubators?

Within the laboratory and industrial sectors, there is a wide variety of furnaces of different types, which adapt to the applications they require, an…

Drying ovens or ovens: Are they sterilizers?

The oven or also called drying oven is a piece of equipment used to dry and sterilize glass and metal containers. It achieves this, thanks to the fact…

Features and care of a laboratory ovens

The laboratory oven is a team used to dry and sterilize glass and metal containers. There are basically two types of oven: those that operate through natural convection and those that operate by forced convection.

FAQs

The delivery time of your Kalstein product will depend on the following elements:

- Whether the equipment of your interest is in stock or needs to be manufactured.

- The type of freight chosen, which can be air or sea.

- Equipment in stock:

– Delivery time (Air): 15-30 days.

– Delivery time (Sea): 45-60 days.

- Equipment not in stock:

– Delivery time (Air): 30-60 days.

– Delivery time (Sea): 60-90 days.

You can make your purchase via:

- By email: [email protected]

- By phone: +33 (0) 1 70 39 26 50

- E-commerce: via Kalstein’s official website in your country.

At Kalstein, we provide our customers with training and technical support through online methods. You can visit our training videos, technical assistance, and advice provided by a Kalstein team on our YouTube channel (Kalstein English). HERE.