A pharmaceutical stability chamber is a laboratory instrument that allows to carry out the so-called stability tests of drugs or medications, these equipment allow to control, monitor and document parameters such as temperature, humidity, differential pressure, lighting, gas levels and other environmental conditions.

These chambers are specialized incubators that can be programmed to mimic environmental conditions, to perform this type of testing where a batch of drugs can be placed inside a stability chamber for a selected period of time (e.g. one month / one year) and thus periodically analyzed to evaluate the impact on the quality of the product. These devices can also be used in studies of accelerated aging and to determine the shelf life and expiration date of pharmaceuticals.

What are drug stability tests?

Drug stability tests are tests done in pharmaceutical industries to evaluate how a drug will be affected by different environmental conditions over time. They are considered a mandatory requirement to introduce new products to the market and thus legalize their trade. Thus, this type of testing is an integral part of many manufacturing processes of products in the pharmaceutical industry, since they show first that there was no error in the final product and second that the product works correctly.

This type of testing can take up to weeks or even months or years according to the product requirement and allow pharmaceutical companies to expose the product (drug) to conditions that could occur along the supply chain, for example, temperature, humidity and exposure to light, as these conditions can cause a drug to deteriorate or lose its efficacy. Stability tests are used not only for pharmaceutical chemicals, but also for products of biological origin such as proteins, polypeptides and conjugates.

What is the purpose of pharmaceutical stability testing?

Pharmaceutical stability tests are intended to document changes in the physicochemical and microbiological characteristics of the pharmaceutical product when exposed to various environmental, temperature, humidity or light conditions. The purpose of these tests is to define precisely the storage conditions of the product, the type of packaging and packaging most suitable for it, as well as to establish its shelf life or expiration.

The stability of pharmaceuticals will depend on key environmental factors such as temperature, humidity and ambient light, as well as other factors that are specific to the product: the physical and chemical properties of the asset it contains and also of the excipients used, the manufacturing process for the transformation thereof, as well as the closure system of the used packaging, the properties of all the materials with which the packaging has been manufactured and the compatibility between the packaging and the product.

How do pharmaceutical stability chambers work?

The pharmaceutical stability chambers function by simulating conditions of relative humidity and temperature, this is achieved thanks to their structure, since they are closed systems that allow recreating, maintaining and controlling a constant temperature and relative humidity inside, simulating the conditions of the places of destination of the products to be able to check the effectiveness of the same during their useful life.

Different pharmaceuticals need different types of conditions for stability tests, but it is virtually impossible to move around the place to achieve the different climatic conditions to which they will be subjected. This is where stability cameras come into play, making work much easier. They are also able to assess the changes that these conditions could cause in product quality in situations of alternative environmental exposure.

What does Kalstein offer you?

Kalstein is a manufacturer of medical and laboratory equipment of the highest quality and the best technology at the best PRICES in the market, so you can make your PURCHASE confidently with us, knowing that you have the service and advice of a company specialized in the field and committed to provide you with safe, economical and effective options to perform your functions in the right way.

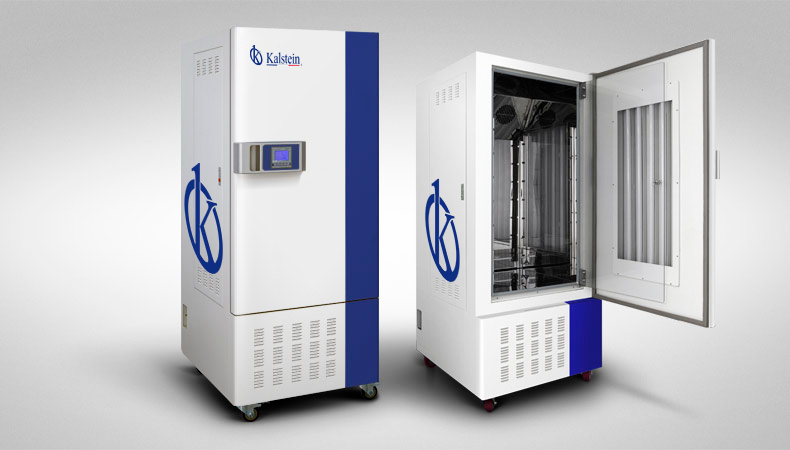

This time we present our Strong Lighting Stability Test Chamber YR053283 // YR053285. It consists of a novel lighting stability testing chamber for pharmaceutical companies for the evaluation of drug failures, accelerated testing and long-term testing of special equipment. Among its main characteristics are:

- World-famous compressor: Balanced cooling technology, automatic defrosting, multiple security system, extended operation, environmental protection, high efficiency and energy saving.

- Automatic defrosting function: original rapid defrosting technology with heat pump, for continuous operation, effectively prevents frost due to continuous evaporator operation.

- Cooling effect manual control system: meets the customer’s terrible working environment.

For more information, we invite you to take a look at: HERE