Heating blankets are a common tool in medical laboratories, offering accurate temperature regulation and perfect heat uniformity for sensitive applications. The need to maintain an accurate method of heating in the laboratory has led to the use of actuators in heating formulas.

They provide the means to distribute heat evenly with the greatest possible precision. If you use actuators properly, you can take full advantage of their benefits to speed up testing procedures and improve your productivity.

Why Use Actuators?

Actuators are electromechanical devices that control the heating processes in heating mats. These devices are installed in a closed loop and allow receiving, processing and sending information with a limited error rate. Actuators are used in these heating mats due to their high accuracy in collecting and sending signals, which allows avoiding unexpected deviations for satisfactory operation.

Actuators are widely used in heating mats to improve accuracy and uniformity in medical laboratory testing processes. These devices offer flexibility, stability and speed in making measurements. Laboratory personnel also benefit from improved safety as supreme accuracy and precision can be achieved. The user of an actuator must follow the proper steps to ensure that this device does not fail, which will greatly improve performance.

Advantages of using actuators in testing

Actuators allow for increased accuracy and stability of heating processes when used in medical laboratory specimen heating mats, resulting in better test results. These devices are able to provide a constant heat, which is evenly distributed over the entire section of the heating mat. This means you have better temperature control in the medical testing process, which translates into a more accurate medical testing process with less chance of errors.

In addition, the actuators can detect any temperature deviations and generate counter signals to precisely regulate the temperature. This allows for a relatively low retest rate, which saves time and resources and improves productivity.

Advantages for Laboratory Personnel

Actuators also offer important safety advantages for laboratory personnel. These devices are capable of detecting and making rapid adjustments when an accidental temperature or other variation occurs, which reduces the risk of injury during the handling of sensitive medical samples.

In addition, the actuators can also detect a presence of moisture inside the heating blanket, providing a reduced risk of electrocution for laboratory personnel.

How to Improve Actuator Performance

The consequences of a malfunctioning actuator can impact the laboratory. Therefore, it is important that the user gets the most out of the actuator’s performance. To achieve this, attention should be paid to a few key aspects that can extend the life of an actuator and make it work more efficiently. Firstly, any form of static current established at the location surrounding the actuator must be eliminated. This can be done by using electrical isolation to prevent any electromagnetic interference.

In addition, the use of poorly maintained cables should be avoided and components should be regularly inspected for signs of wear and tear. Regular cleaning also helps to improve the performance of an actuator. This is recommended whenever the actuator detects a failure. These simple measures can make an actuator have a longer service life and deliver superior performance.

What we offer at Kalstein

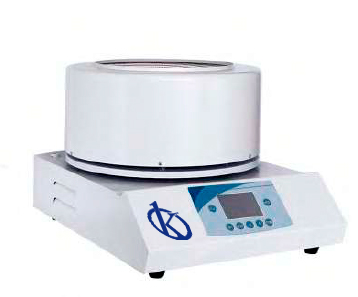

YR multiple heating mantles are designed for repetitive extraction (Kjeldahl, Soxhlet and other extraction procedures), laboratory reflux and distillation applications, learn more about our equipment HERE, as we are manufacturers we guarantee quality materials, competitive price and purchasing advice. HERE