The microplate washer is laboratory equipment designed to meet practical methods where several processes are used where substances, nutrients or wash solutions are spread on each well and then removed. In order to achieve greater reliability and accuracy of results, it is essential that the wells are emptied and washed with a solution several times to remove any residue.

In the course for the determination of diseases as is the case with the Ebola virus, the use of Elisa with the microplate washer are performed the necessary practices making it fundamental to deposit each of the wells to a number of times. Among the laboratory tests, Elisa is used for serological diagnosis towards the determination of the virus and the World Health Organization (WHO), the disease can spread to through infected body fluids, as well as through direct contact with carrier remains or contaminated animals.

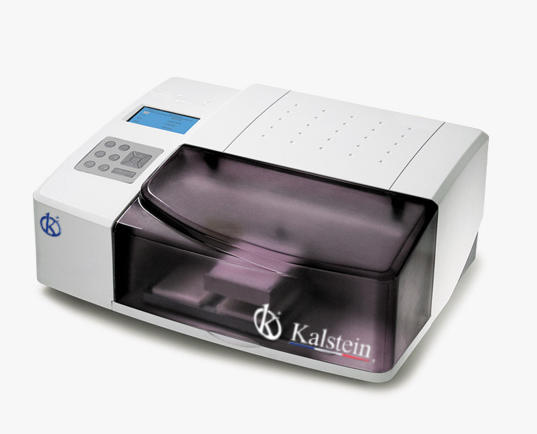

That said, with the use of the equipment that Kalstein has for you, it will allow each of the research and development processes to obtain reliable results, thanks to the technology with which the microplate washer works and its multiple functions and features, such as uniformity throughout the washing process and heads for 96 wells.

Advantages of the Microplate Washer

Using the microplate washer in conjunction with the Elisa reader, the evaluation depends on two factors: epidemiological risk and presence of fever. Therefore, the tests must be studied to measure the risk of infection control and with the Elisa technique the sample is introduced into a polyethylene plastic device to be mixed with certain antibodies that will stimulate and create a color change that will show the presence of the virus.

The microplate washer therefore plays an important role for these determinations, because in immunological practices, the reagent remains stuck to the surface of the plate and the plate must be washed before any process, to avoid the formation of colors where the antigen was absent. All washing operations can be performed manually or automatically.

With the Kalstein microplate washer the practices are performed by individually aspirating the liquid from each well with pipettes linked to a vacuum system over the entire column of wells at once.

Microplate washer mechanism

Equipment-automated processes automatically add reagents, deposit liquid from wells and serially dilute samples. Works the same way as manual processes. Typically, the microplates are in a horizontal position and a series of needle-like devices, in which the wash medium is added from the top of the plate to each well followed by a rapid extraction of the wash substances through each set of suction waters, using a vacuum suction mechanism.

Similarly, the extraction pipettes must remove as much substance as possible for the washing process to be effective and reduce the residual amount of reagents present in the wells. This requires precise and sophisticated technology, and Kalstein has the ideal equipment, which ensures safety by using liquid sensor methods for the washing processes. The exclusion of substances is particularly important when working with very small quantities of liquids. The methods of washing the equipment that require the use of needles, offers the reduction of maintenance of the same, preventing residual contamination between washes, eliminating any obstacles on the needles, maximizing the speed of the processes and allowing the reduction of the operations of the micro-plate washes in a conventional way.

Washing machine in microplate (Elisa) brand Kalstein

At Kalstein, we offer you the best technology of medical equipment, and the microplate washing machine belonging to YR series, are the ideal ones that adapt to the users’ needs. We can provide our new equipment which has special functions, such as: Double layer washing at the same time, high efficiency. It contains three bottles of high concentration liquid of 10000 ml and operates by 7″ color touch screen. In addition, it has other attractive features, which you can enjoy our catalog from HERE