Description

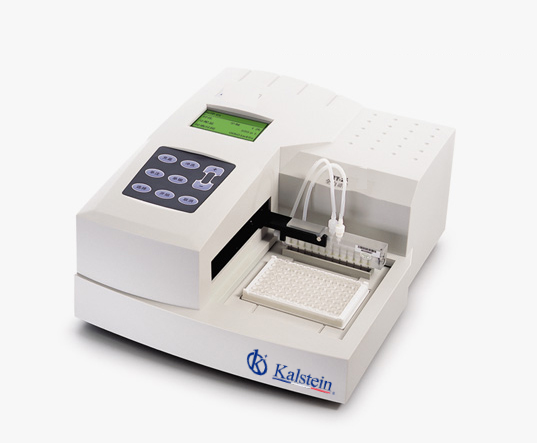

The Microplate Washer YR06088 sets a new standard in laboratory automation by offering precise and reliable washing performance tailored to user-defined protocols. Designed to accommodate 96 or 48 well plates with round, flat, or V-shaped bottoms, this microprocessor-controlled device ensures optimal washing with minimal residual volume. Featuring dual-needle manifolds for both aspiration and dispensation, the YR06088 significantly reduces the risk of cross-contamination, making it an ideal choice for rigorous scientific environments. Its liquid level detection and alert function further enhance operational efficiency, ensuring seamless workflow management.

Market Price

In the competitive landscape of laboratory equipment, the Microplate Washer YR06088 is a standout choice, offering advanced features and robust performance within a market price range typically between $235,000 to $236,500 USD. Investing in this sophisticated device allows laboratories to elevate their productivity and accuracy in microplate washing tasks.

Frequently Asked Questions

Q: Can the Microplate Washer YR06088 handle different plate types?

A: Yes, it supports flat, U, and V-bottom strips and plates.

Q: Does this model offer any safety alerts?

A: Absolutely, it features an alarm for insufficient washing liquids, ensuring the washing process is not interrupted.

Advantages and Disadvantages

Advantages: The Microplate Washer YR06088 is praised for its precision and flexibility, accommodating various microplate types and washing volumes. Its memory capacity, with space for 50 protocols, allows for extensive customization and automation.

Disadvantages: The upfront investment may be a consideration for smaller labs, and it requires proper maintenance to ensure longevity and optimal performance.

Product Usage in the Field

Widely adopted in research laboratories, clinical diagnostics, and biotech firms, the Microplate Washer YR06088 excels in efficiently processing well plates for ELISA assays. Its reduced cross-contamination risk and adjustable washing volumes make it invaluable for high-throughput screening and other repetitive testing scenarios.

Recommendations

For optimal use, it is recommended to routinely calibrate the washer’s settings and check fluid levels to prevent operational pauses. Utilizing the device’s RS232 port allows for easy data transfer and integration into larger automated systems. By taking advantage of these features, laboratories can maximize efficiency and accuracy in their workflows.

Features

- Microprocessor-controlled washing for tailored protocols

- Support for flat, U, and V-bottom strips and plates

- Two-needle manifold to reduce cross-contamination

- Advanced liquid level detection with alert system

Technical Specifications

| Model | YR06088 |

| Washing | 96 or 48 well plates with round, flat or V-shaped bottoms. |

| Includes head | 8 and 12 channel. |

| Washing volume: | 50-3000 ml with 8 channel head, 50-2000 ml with the 12 channel head. |

| Drying time: | 0 to 24 hours. |

| Memory: | 50 washing protocols with up to 99 washing cycles in each. |

| Residual volume: | <3 ul. |

| Includes | Two 2 liter bottles, for washing liquid and for waste. |

| Alarm | For lack of washing liquids. |

| Port | RS232. |

| Dimensions: | 39x33x18 cm. Weight: 9 kg. |