As it is well known, a thermal cycler is a device used in Molecular Biology that allows to realize the temperature cycles necessary for the amplification of several strands of DNA in the PCR technique (Polymerase chain reaction). The most common model consists of a block of electrical resistance that distributes a homogeneous temperature through a plate during times that can be programmable, usually with temperature ranges of 4 ° C to 96 ° C where denaturation, hybridization and spreading occur. a molecule of DNA. The current thermocyclers are capable of rapid temperature changes that allow the three steps of the PCR reaction to be cycled.

The maintenance of the thermal cycler is very important because many failures in these can be avoided with a daily maintenance or after each execution of protocols in them, apart from the necessary annual preventive maintenance. Below is a series of steps to follow to keep your valuable thermocycler in optimal working conditions (Remember to disconnect the flow of electrical current and verify that your equipment is no longer in high temperature).

Clean the housing or external part of the thermal cycler with a soft cleaning cloth or paper, this should be lightly moistened with a soap solution of neutral pH, otherwise you can use the cleaning cloths of computers which can be purchased in any dedicated house ( do not use waxes or abrasives).

Proceed to clean the wells (before making sure they are not hot), the wells should never have material adhered to them, the cleaning process is simple and should be done as described below: use swabs or swabs, these should be wet ideally with isopropyl alcohol / isopropanol, failing with methanol. If your wells of the thermal block are badly attacked by external material adhered to them, you should proceed with caution and perform the following operation dilute sodium hypochlorite of any commercial house in a 1: 100 ratio with water, with a swab or moistened swab in the liquid / solution clean the wells, immediately after use 95% ethanol; never leave the wells moistened, proceed to clean and remove residual moisture with a dry swab or swab.

The thermal area of the lid should be cleaned with a cloth or soft cleaning paper moistened with isopropyl alcohol. These described steps are valid before a spill originated, remember not to allow the liquids to dry in the areas mentioned above affect the performance of the sensors giving false data to the internal processors.

Another part of the continuous maintenance is the cleaning of the vents, its thermocycler depends a lot on the ventilation system, it should not be obstructed by particles adhered to the ventilation system and for its optimal functioning it should not have other equipment that emanates heat or has air demand to cool in a radius of 30 cm .; The cleaning process is as follows; disconnect the source of power be sure to wait a few minutes as the equipment could still have electrical charge (try to eliminate its static by touching a metal part of your installation as a door knob), take a small brush and gently clean the vents, if you believe that some particle could try to penetrate when passing the brush just avoid that area and continue, after the process can pass a cloth moistened with isopropyl alcohol / isopropanol or a soft cloth cleaning computers (do not use waxes).

Remember the cleaning of the vents is important to prevent overheating and failures in the integrated plates. Never use abrasives, solvents or acid solutions that damage the external and internal part of your thermal cycler.

If the thermal cycler has been attacked by external particles inside it has suffered spills, stop the protocol, disconnect, let cool, proceed with the maintenance method described.

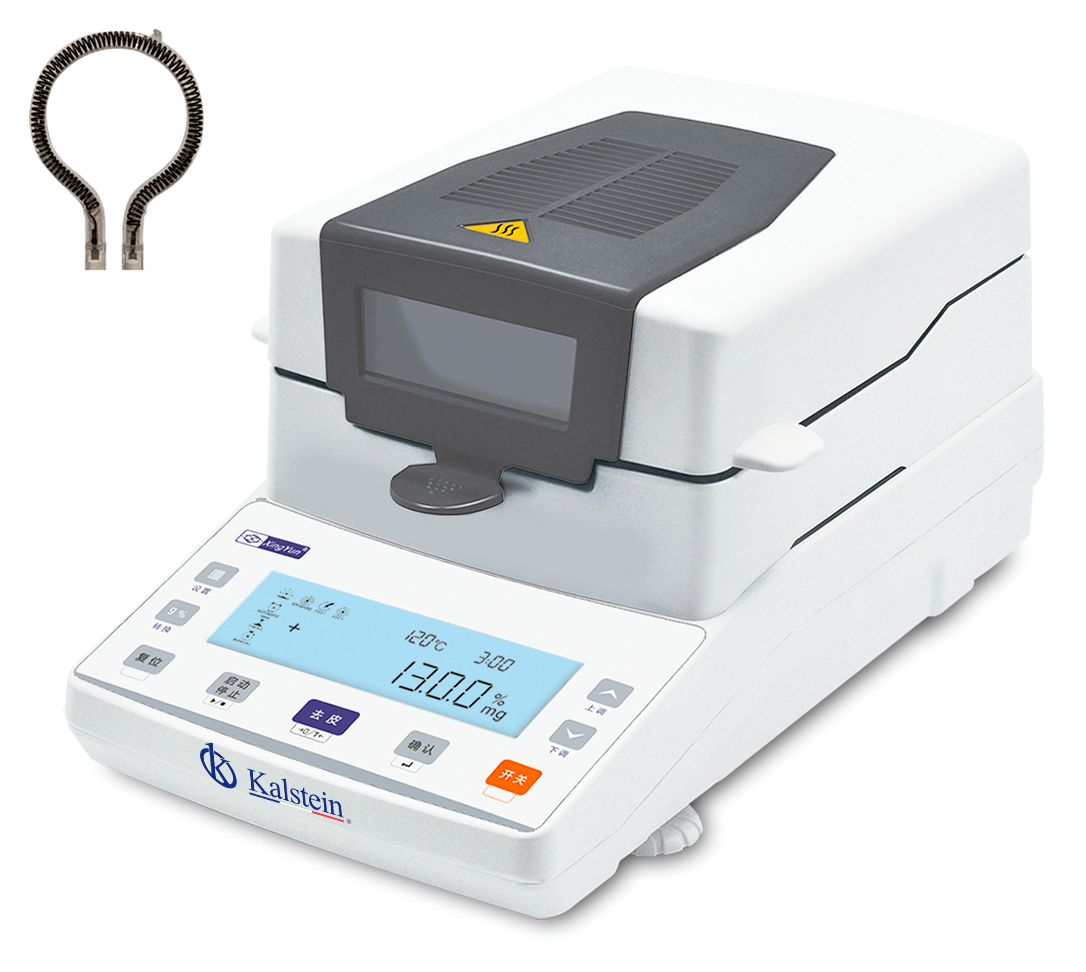

At Kalstein we offer you an excellent range of thermal cyclers that range from economical options to state-of-the-art equipment, recognized for their reliability, precision and ease of use. That’s why we invite you to take a look at our thermal cyclers available HERE