Description

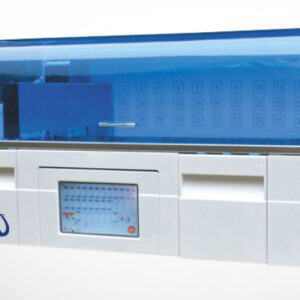

The YR435 Automatic Fabric Dyeer is a state-of-the-art device engineered to enhance the efficiency and quality of fabric dyeing processes in various industrial environments. Featuring an intelligent water inlet and outlet system, this high-tech machine guarantees optimal resource use by maintaining water cleanliness throughout the dyeing stages. The premium imported LCD touchscreen offers a responsive, user-friendly interface, simplifying operations and boosting productivity. Additionally, its ergonomic design caters to the diverse needs of users, providing a customizable and efficient workflow experience.

Market Price

The price of the YR435 Automatic Fabric Dyeer varies depending on the supplier and additional specifications. Typically, similar high-quality automatic dyeers are priced between $15,000 and $25,000 USD. This range reflects the advanced technology and automatic functionalities it offers, making it an attractive option for industries focusing on research and large-scale production.

Frequently Asked Questions

- How many fabric batches can the YR435 process simultaneously?

The YR435 can process up to 72 batches at once, significantly enhancing production efficiency. - Is the YR435 Automatic Fabric Dyeer easy to operate and maintain?

Yes, its intuitive design, LCD touchscreen, and automatic features streamline both operation and maintenance, ensuring long-term reliability and energy conservation.

Advantages and Disadvantages

Advantages:

- Processes up to 72 dye batches concurrently.

- Smart water system for optimal efficiency.

- High-quality touchscreen for straightforward operation.

- Ergonomic and adaptable design for user-friendly experience.

- Automatic memory function for preset configurations.

Disadvantages:

- Higher initial investment may be necessary.

- Size and weight could pose challenges for smaller facilities.

Product Use in the Field

The YR435 Automatic Fabric Dyeer is ideal for industries that require efficient processing of large fabric volumes. Its ability to handle up to 72 batches, combined with its 14 processing cups (12 for dye, 1 for washing, and 1 for drying), ensures a seamless, rapid operation. The low-noise and wear-resistant system guarantee dependable performance, while its eco-friendly design provides a safe and sustainable dyeing process.

Recommendations

For optimal performance, adhere to the manufacturer’s instructions for regular maintenance and calibration of the YR435. Training staff adequately on the equipment ensures consistent, high-quality dyeing results, thus extending the device’s operational life. Experience precision and efficiency in your production processes by requesting a personalized quote or generating an automatic quote through Kalstein Plus today!

Technical Specifications

| Model | YR435 |

| Number of processing cups | 14 (12 reagent cups, the 8th station for washing and the first drying station) |

| Processing time duration for each station | Adjustable within 0 min 0 s – 59 min 59 s for each station |

| Individual cup capacity | 1500ml |

| Number of slides to be processed at the same time | 72 pieces |

| Working voltage | AC 220V ± 10% 50Hz (standard model); AC110V ± 10% 60Hz |

| Power requirements | 500W |

| Dimensions | 1180 × 420 × 470 mm (W × D × H) |

| Net Weight | 70kg |