Freeze drying has become a standard practice in the pharmaceutical industry, since the beginning of its first applications around the 40’s. Since then, the freeze dryer has gone from being a simple vacuum drying equipment to become a highly sophisticated system and integrated, which combines a series of processes to guarantee a systematic production according to technical and biological specifications.

Lyophilization consists of a process that aims to separate the liquid (water or another solvent) from an organic material, or from a solution, by freezing and then sublimating the ice under reduced pressure, thus generating a dehydrated product without altering its composition. qualitative and quantitative, that is, preserving the molecular structure of the substance to be preserved. This is achieved thanks to the use of a freeze dryer.

A lyophilizer is made up of a dry chamber or lyophilization chamber, a condenser with a refrigeration circuit and a vacuum system.

Among the lyophilized products we find antibiotics, bacteria, serums, vaccines, diagnostic medications, biotechnological products, proteins, as well as products with cells, tissues and chemicals. The product is subjected to a freezing process at a pressure below atmospheric. Then, and in an initial drying phase defined as primary drying, the water is removed (in the form of ice) by sublimation; in the second phase, secondary drying is removed by desorption.

Freeze drying is considered one of the safest and most widely used techniques for sample preparation in the pharmaceutical industry. It has been used in the preservation of biological materials such as blood plasma, serum, hormones, and biologically complex pharmaceuticals such as vaccines, sera, and antidotes, as well as in many diverse research projects in this industry, as this process offers excellent retention. of the molecular structures of biological samples.

That is why lyophilizers are of vital importance in the pharmaceutical area, since the process carried out in these equipment aims to reduce the lability of these very delicate components present in the formulation.

A lyophilization cycle can be divided mainly into four stages: freezing, evacuation, primary drying and secondary drying. Each of these stages are important in themselves, although the most critical factors to take into account in the process occur in the course of freezing and primary drying.

Advantages of lyophilization

- Maintains the chemical stability of the product, the enzyme preparations do not suffer alterations.

- Inhibits the growth of microorganisms.

- Inhibits deterioration by chemical reactions. Oxidation phenomena are eliminated, since it is operated and packaged under vacuum.

- Facilitates the storage, transport and preservation of products. As the remaining moisture is negligible, the product can be stored for an unlimited time, constituting products with long stability.

- It allows to recover the properties of the conserved material only by rehydrating it. The high porosity facilitates quick reconstitution by adding water or the appropriate solvent.

- Prevents damage caused by heat on the material to be preserved, due to the fact that high temperatures are not used. The temperature to which the product is subjected is below those to which many unstable substances undergo chemical changes.

- Decrease in additives and preservatives.

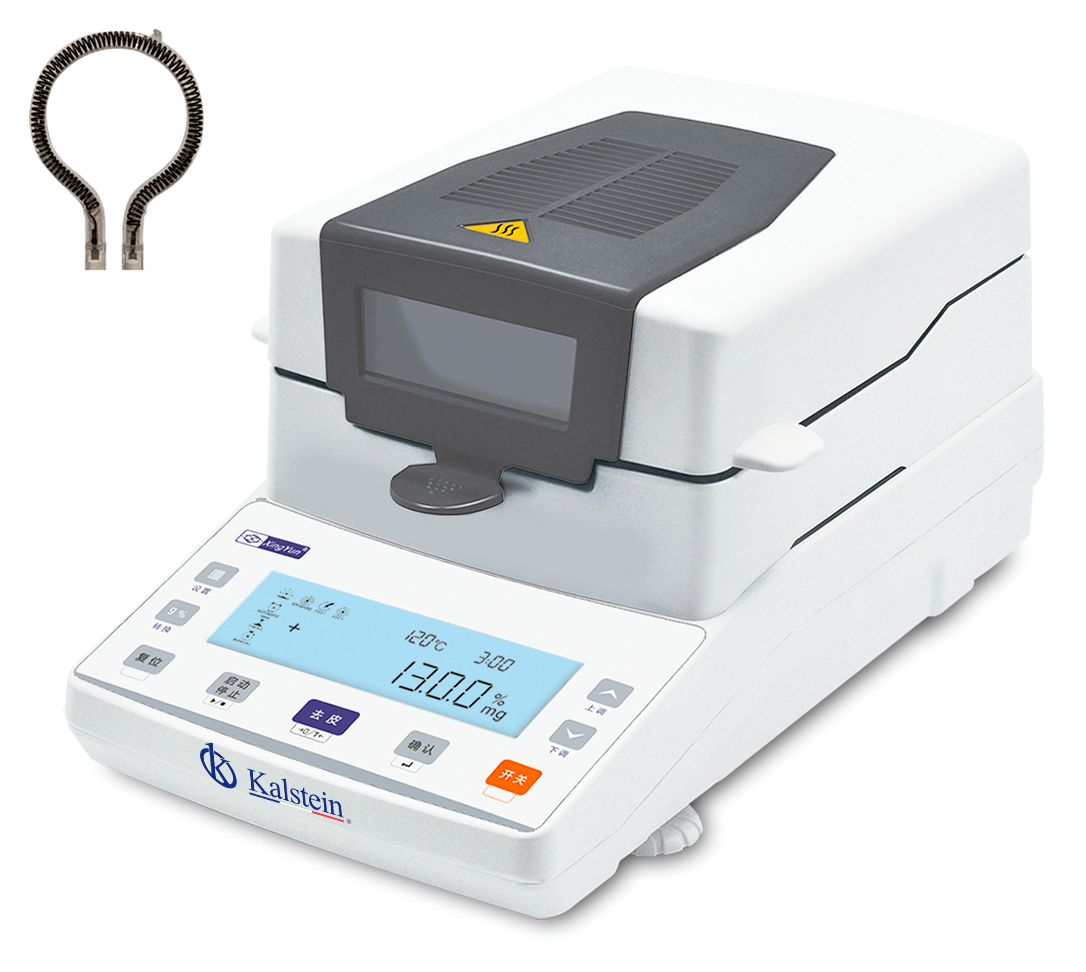

At Kalstein we are MANUFACTURERS of medical and laboratory equipment of the highest quality and at the best PRICES, and we offer you excellent freeze-drying equipment. That is why we invite you to take a look at the Products HERE