The pH analyzers have two general maintenance procedures: those directed to the analyzer body and those directed to the pH detector probe (electrodes).

General maintenance procedures for the body of the pH analyzer (Frequency: Every six months)

• Examine the exterior of the equipment and assess its general physical condition. Check the cleanliness of the covers and the adjustment of them.

• Test the connection cable and its coupling system. Check that they are in good condition and that they are clean.

• Examine the controls of the equipment. Verify that they are in good condition and that they can be operated without difficulty.

• Verify that the subway is in good condition. For this verification, the instrument must be disconnected from the power supply line. Adjust the pointer to zero (0), using the thumbscrew that is usually under the pointer of the pointer. If the equipment has an indicator screen, check its normal operation.

• Confirm that the power indicator -bomble or diode- operates normally.

• Check the status of the electrode holder arm. Examine the mechanism for mounting and fixing the electrode, in order to prevent the electrode from coming loose. Check that the height adjustment works correctly.

• Check the batteries -if applicable-; change if necessary.

• Perform a functional test by measuring the pH of a known solution.

• Inspect leakage currents and ground connection.

Tips for basic electrode maintenance

The detector electrode requires periodic maintenance every four months of the conductive solution, so that it can obtain accurate readings.

The recommended processes to replenish the electrolytic solution are the following:

• Remove the detector electrode from the storage buffer solution.

• Rinse the detector electrode with plenty of distilled water.

• Remove the upper cover of the detector electrode.

• Fill the detector electrode with a saturated solution of potassium chloride (KCl). Use the syringe or applicator that accompanies the KCl solution. The filling is carried out through the conduit that protects the upper cover of the electrode. Verify that the tip of the syringe does not touch the inside of the electrode.

• Wrap a small part of the top cover of the electrode to cover the upper opening of the electrode.

• Use the tip of the syringe needle to pierce the area of the cap that covers the opening, in order to allow a balance of pressure between the inside and the outside of the electrode.

• Rinse the electrode with distilled water.

• Keep the electrode inside the storage buffer solution, as long as it is not in use. Cleaning the electrode The type of cleaning required by the electrode depends on the type of contaminant that may have affected it. The most common procedures are summarized below.

• General cleaning. Soak the pH electrode in a 0.1 M solution of hydrochloric acid (HCl) or 0.1 M HNO3, for 20 minutes. Rinse with running water before use.

• Removal of deposits and bacteria. Soak the pH electrode in a 1:10 solution of household bleach, for 10 minutes. Rinse with plenty of water before using.

• Oil and grease cleaning. Rinse the pH electrode with a medium detergent or with methyl alcohol. Rinse with water before use.

• Cleaning of protein deposits. Soak the pH electrode in 1% pepsin in 0.1 M hydrochloric acid, for 5 minutes. Rinse with water before use. After performing any cleaning operation, it is advisable to rinse with deionized water and fill the reference electrode before use.

Other care

• Do not hit the electrode. Since its structure is usually made of glass and this material is very fragile – it breaks before it is deformed – it is necessary to handle it carefully, avoiding that it suffers blows, shocks or falls.

• Remember that the electrode is an element of consumption and that it has a limited lifespan.

• While not in use, keep the electrode inside the storage buffer solution

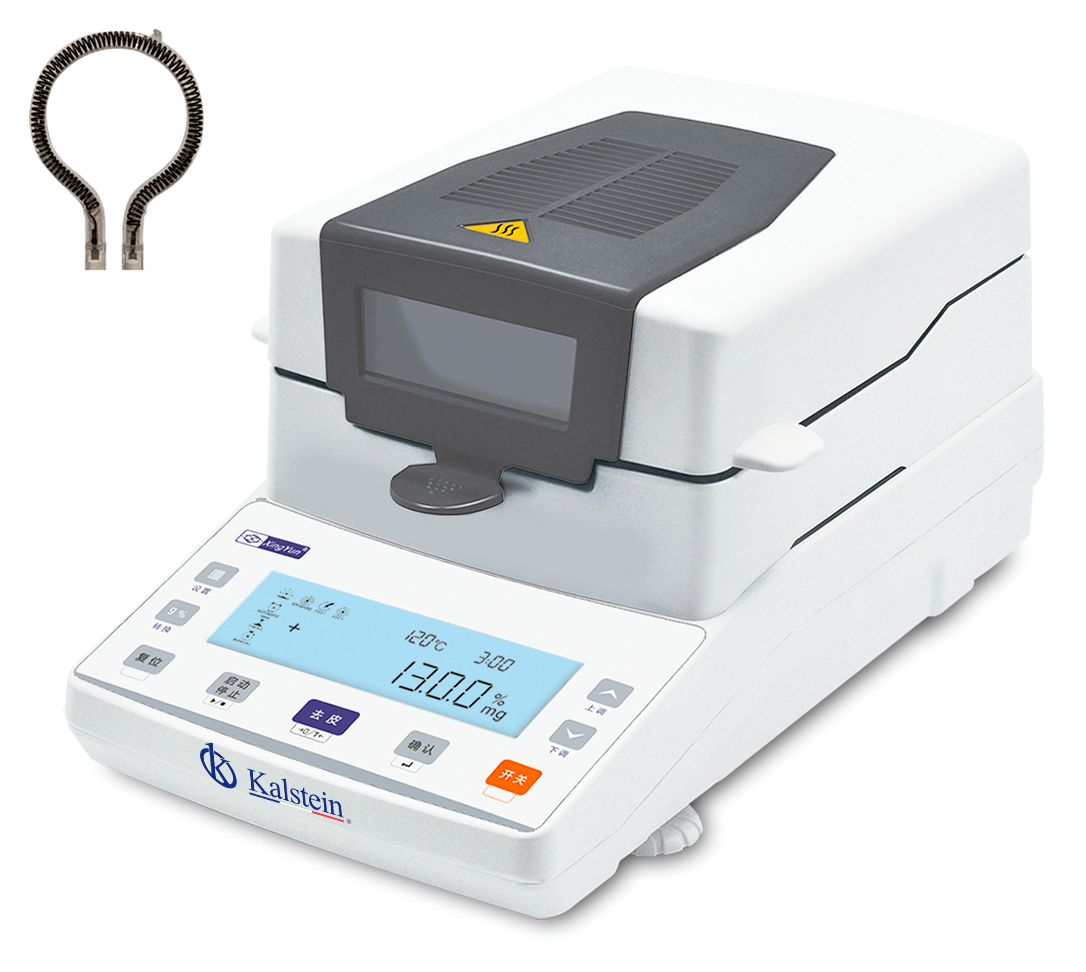

In Kalstein we offer you an excellent range of pH analyzers ranging from economic options to the most advanced equipment, recognized for their reliability, precision and ease of use. That’s why we invite you to take a look at our available equipment in HERE