Currently, there are methods that ensure total gas solution, optimizing the use of oxygen to remove excess gas contents, and oxygen meters deliver these solutions to breweries, where the average is usually ±0.5 ppm the appropriate amount. In order to guarantee a constant fermentation and a minimal injury of the beer by the excessive production of yeast.

Therefore, because of the existence of these atoms, the products have to be monitored by means of oxygen meters. With this, you can get reliable results, as they are able to display typical values of and apply correct methods for high-quality production.

Measurements of oxygen in the stirring

In order to take into account the characteristic dissolved oxygen values, these may vary during beer production, with measurements not exceeding 0,05 ppm, depending on whether the measurement is made on purified beers or beer extract, where all gases will have to be completely dissolved before being calculated by the oxygen meter.

It should be stressed that, in practice, certain measures must be respected, such as:

- The lid should be fully opened and control the flow of beer using the flow control on the equipment side.

- The sensor shall have the sample pressure and ensure that it does not contain bubbles so as not to alter the results.

- In order to avoid degassing, the flow rate of the sensors must be low to allow determination.

- No air should be drawn during the measurement processes to ensure a faster and error-free response.

- It is important to take temperature into account

It should be stressed that beer is a major economic interest and that, if oxidation changes occur, the consequences are irreversible. It is therefore appropriate to recommend that oxygen sensors be fully calibrated and installed in the beer production area.

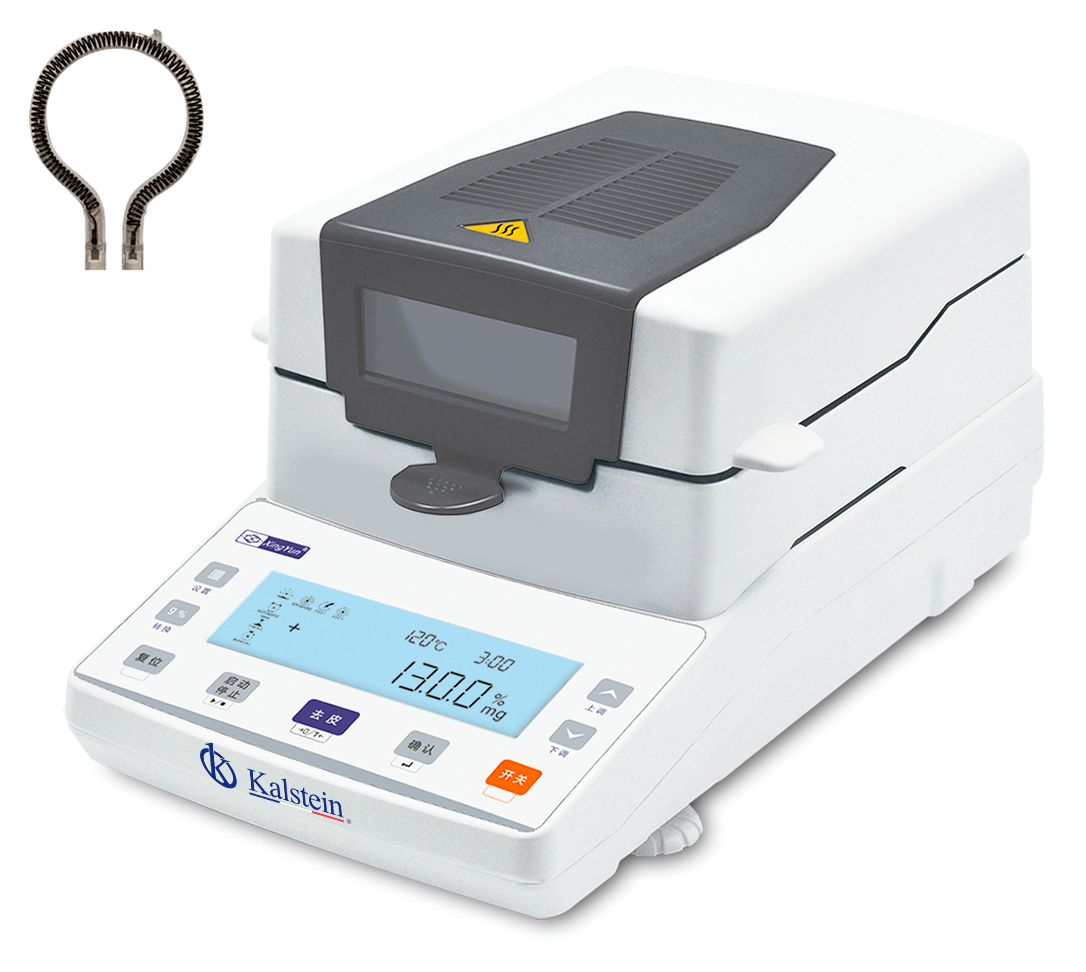

Our Kalstein model has programmable points that allow measurements to meet the requirements of this sector, because dissolved oxygen meters have a value that adapts to any temperature, and sensors have alarm systems that immediately warn when connections are empty or clean.

Oxygen meters to demonstrate product quality

In the brewing industry, it is recommended to use Kalstein dissolved oxygen gages, which are the most ideal for these practices, because in the process it applies a gas pressure in the sample to the vacuum so that the content passes through the oxygen sensors and can calculate the concentration levels. Therefore, in order to carry out these actions, the brewing industry must do so as follows:

- The applied oxygen pressure must exceed the total dissolved gas pressure in the beer contents to avoid bubbles.

- Containers should be measured after filling and before pasteurization because oxygen reacts very rapidly with beer through mechanisms.

- Containers should be shaken before use to equalize dissolved gases and empty space.

As a result, the oxygen accumulated in the sample promotes the degradation of beer taste. In other words, the higher the quality of oxygen, the more the taste changes. As a result, the amounts of oxygen in the packages are analyzed to determine whether they are from the filling processes. In other words, the oxygen consumption of a prepackaged beer is transformed according to temperature, type of beer and yeast.

Kalstein brand dissolved oxygen meters

In this category, our users will find the right accessories for all the equipment you want to use. This includes a wide choice of dissolved oxygen flow meters from the YR series. Which meets certain special characteristics such as: 1 or 2 calibration points. Temperature compensation from 0 to 50 ° C / 32 to 122 ° F, automatic. Pressure correction from 60.0 to 112.5 kPa / 450 to 850 mmHg, manual. Salinity correction 0.0 to 50.0 g/L, manual.

If you need to know more about our range of equipment, we invite you to consult our catalog HERE