Sterilization is essential in the field of medicine. Sterilization describes the process of ridding objects and materials of living microorganisms. Sterilization is used mostly in doctors’ offices or hospitals, where people with weak immune systems may be exposed to pathogenic germs.

To avoid contamination, it is necessary to comply with hygiene regulations and prescriptions, including sterilization. In the sterilization of materials and objects is achieved in the best case kill all viruses, spores, germs etc. However, in practice it is not always achieved 100%, because certain types of germs are very resistant.

Sterilization is above disinfection, and is applied when disinfectants do not guarantee the sterility test. The sterilization can be carried out by thermal or chemical procedures. For this purpose, a range of devices is offered in sterilization that allow optimal sterilization. The difficulty lies in developing devices that allow the sterility test to be carried out quantitatively. This includes, for example, laboratory autoclaves, which heat water and the steam produced displaces the air. In sterilization there is also steam sterilization. This is normally carried out at 121 ° C with a vapor pressure of 2 bar. This sterilization allows that after 15 or 20 minutes all the microorganisms have been killed. But not only the materials and objects are carriers of bacteria and microorganisms; they are also in the air. That is why it also requires a clean air. In the medical sector, special extraction systems are installed.

Thanks to many developed systems it is possible to ensure our health in the environment. This prevents pandemics and the proliferation of diseases. Another aspect of sterile technique covers the food processing sector. The preserves and the means of packaging that are in direct contact with the food are sprayed with antiseptics that kill the germs that may have arisen during manufacture. In addition to protecting the human being from pathogenic germs, it is also necessary to avoid premature decomposition of food by applying sterilization.

Different forms of sterilization:

Sterilization by heating: For this the kinetics of destruction of microorganisms is used. By developing high temperatures for a certain period of time it is possible to guarantee the decomposition of microorganisms. This includes the following categories of sterile technique: steam sterilization, hot air sterilization and fractional sterilization.

Chemical sterilization: Covers sterilization with certain chemical elements, such as formaldehyde, ethylene oxide, etc. This type of sterilization, usually with thermolabile materials. There are liquid antiseptics that apply to materials, or dry antiseptics, where germs are killed by gas. It is also possible to work with ionizing radiation (UV radiation, X-rays, gamma radiation), or plasma sterilization products.

Typical pressure cycles used in autoclaves are:

• Cycle for fabrics, filtering units and discards.

• Cycle for plastic and laboratory glass.

• Cycle used mainly for discards.

The performance of the process can be confirmed by monitoring the color changes on the indicator tape that is usually applied to the packages or products that are entered into the autoclave. Biological indicators can also be used, such as Attests, which contains spores of Bacillus Sterothermophilus, which are among the most resistant organisms that an autoclave must destroy. After a batch in the autoclave, the inner glass of the ampoule of the Attest is broken, whereby the spores penetrate into a differential liquid medium. If the autoclave has destroyed all the spores, the liquid remains blue. Otherwise, the spores will be metabolized and will cause a change to the yellow color after two days of incubation at 56 ° C.

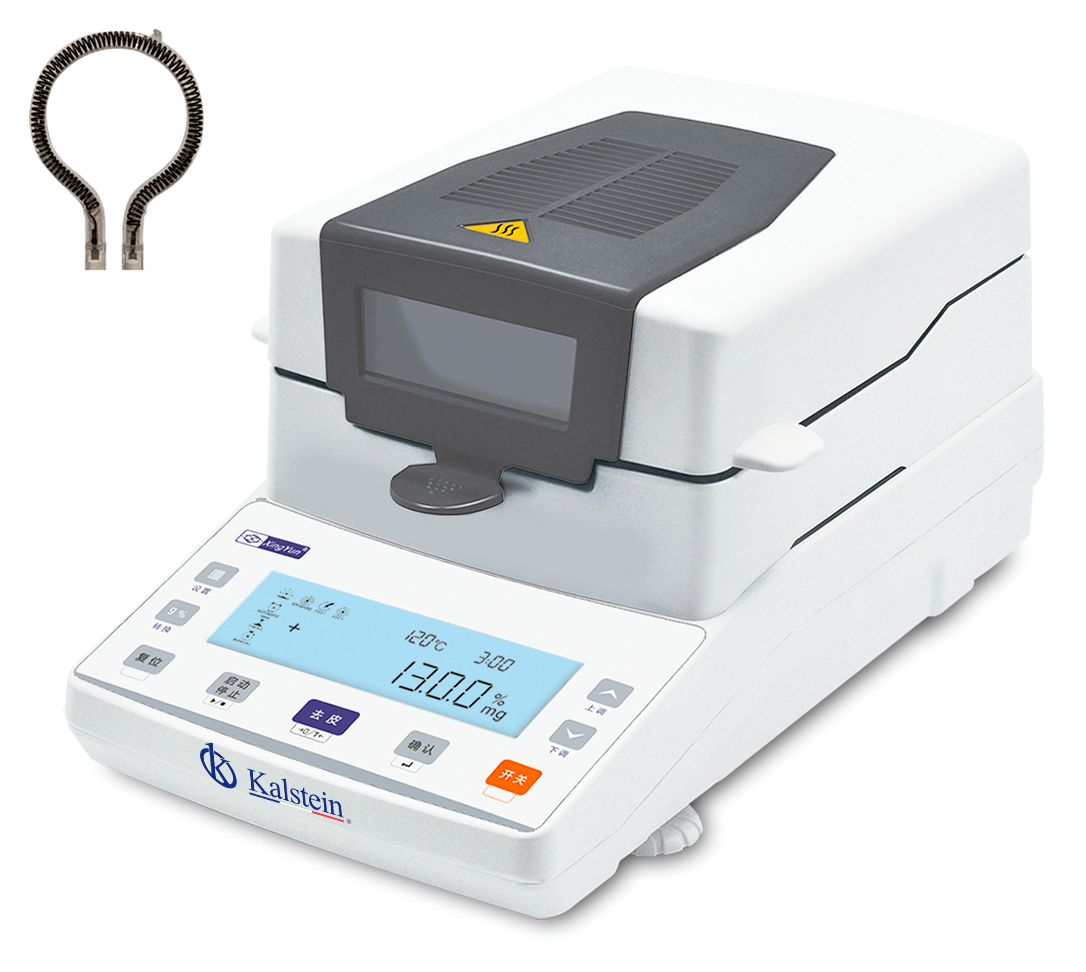

At Kalstein, we have designed autoclaves that efficiently meet the stringent safety and sterilization requirements of large health centers. That’s why we invite you to take a look at our one of the autoclaves available at HERE