The microtome is a laboratory equipment of histology, used to cut the samples in thin caps, from a paraffin base, so that light will pass them into them and be studied from a microscopic perspective. It also has tools, such as a blade, a sample holder and a mechanical system, which allows to advance the paraffin block, with the sample inside, on the blade a distance interval that corresponds to the thickness of the section to be obtained, and make the cut.

Types and Functions of Microtomes

Within the laboratory field, the microtome is widely used; in the hospital health sectors, as well as in agricultural institutes, epidemic prevention center, veterinary center, in the office of experts in public medicine and scientific research and laboratory institutes. It has different functions depending on the types, which are:

- Sliding: it is composed of a fixed sample holder and a blade that is fixed on a slider, to ensure a stable cut. The cut is pressed through the sample and allows cuts with a thickness of 1 to 60 µm.

- Rotation: Also known as Minot microtome, they have a fixed blade and a mobile sample holder. The sample holder is driven by a steering wheel and transforms into a straight motion. Normally the sample holder of these microtomes moves in the downward direction. The prepared samples accumulate on the blade and allow to prepare between 1 and 60 µm.

- Freezing: These are a subcategory of rotating microtomes. The test is in a freezer container that is cooled with nitrogen, for example. Low temperature increases the hardness of the test.

- Ultramicrotomes: the samples are prepared for transmission electron microscopes. Because the preparations must be extremely fine, they have special blades and a very fine feed, driven by thermal expansion. The use of these allows a thickness of 10 to 500 µm.

- Laser: They use a special laser for cutting. These stand out for their strong focus and very short pulse durations, allowing very fine cutting of the tests without causing thermal damage to the test material. In addition, samples with a thickness of between 10 and 100 µm can be prepared.

Recommendations for Use

Handling any microtome should be done with care, as the user manipulates sharp instruments and may be in an accident. Therefore, the following recommendations arise:

- The lack of edge, or irregular profile of the blades, are the main reason for the bad cuts.

- It is necessary that the surface where the equipment is located is free of dirt, in addition, the equipment must be lubricated with light neutral grease. Sliding surfaces must always be oiled.

- Comply with previous maintenance for your accuracy.

- It should be covered when not in use and always kept clean.

- The inclusion medium must be chosen correctly, according to its grain or crystalline structure.

- The hardness of the paraffin should be chosen according to the hardness of the specimen and the temperature at which the cut will be made, to prevent an inadequate contraction.

In this sense, the section of the cut is not dependent on a single factor, but on several factors, such as the accuracy of the microtome mechanism, the blade edge, specimen preparation and temperature and operator experience.

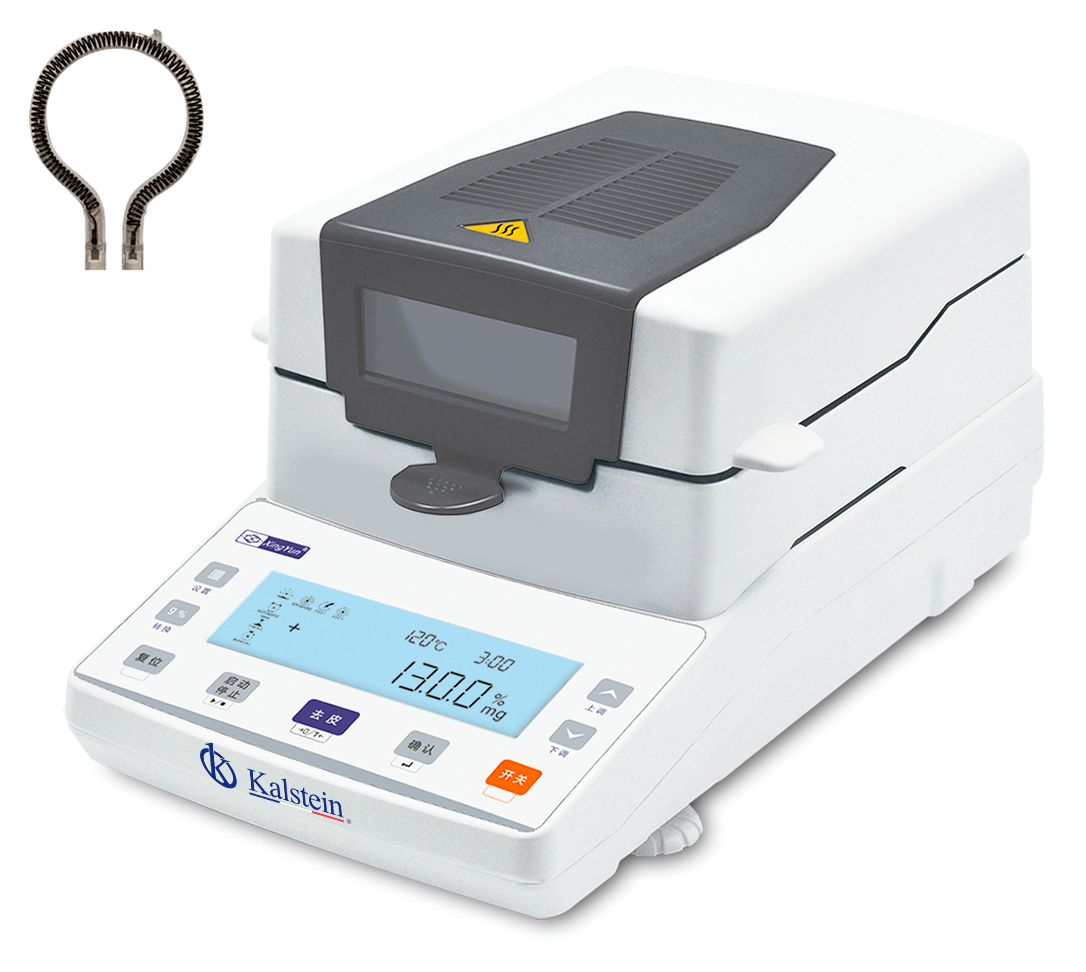

Kalstein Microtome

At Kalstein, we are able to meet the demands of our users in the selection of laboratory equipment. We offer you, the Microtome, corresponding to the YR series, with multiple attractive features, such as its great functionality and attractive design, are the key features of our microtome. X-axis 360°, Y-axis 12° universal rotation, pressure weaving chuck, easier and faster to install the organization. Equipped with a rubber instrument rack and waste box. The blade holder is equipped with a blade pusher and a blade protector to cover the entire length of

the blade, which protects the user safely. To learn more about our products, visit HERE At Kalstein, as manufacturers, we provide all the advice our customers need, for what their purchase is ideal, and at excellent prices. Come visit us at HERE