An autoclave is a type of sterilizing equipment that uses high pressure and steam to sanitize tools, equipment and supplies. They are common in healthcare settings, but are also used in many other industries, including the beauty industry.

They work by using high pressure and steam to kill bacteria and other microorganisms. The steam is generated by boiling water, and the pressure is created by a pump. The autoclave cycle usually takes about 15 minutes.

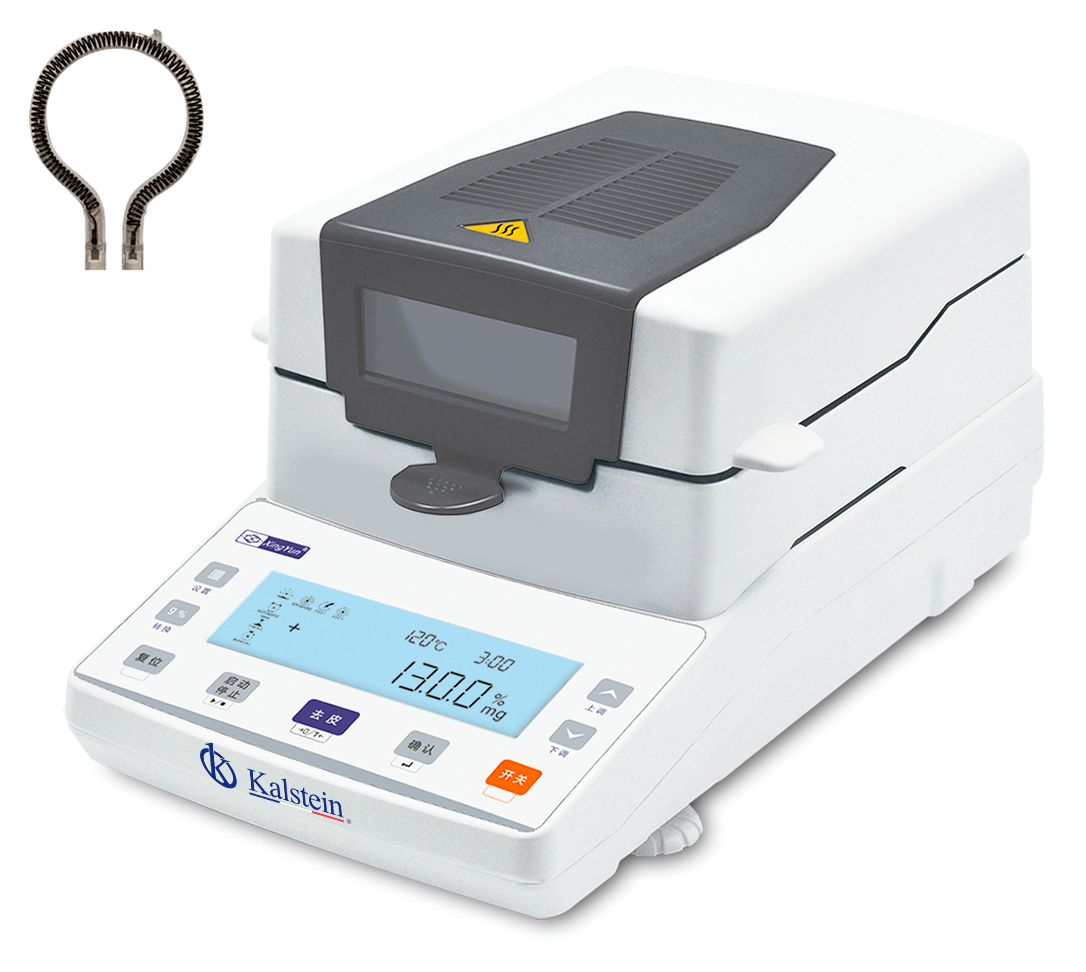

In that regard, the beauty industry has embraced the autoclave as a safe and effective way to disinfect tools and supplies. Many beauty salons and spas now have one on site, and Kalstein can provide you with the ideal equipment, as you can select two programs of 121°C and 134°C. In addition to the LED display screen, it can show the temperature with high accuracy, which can be 0.01 ° C.

Participation of the Autoclave for Cosmetology

Autoclaving is an important part of any salon or spa’s sterilization protocol. All tools and supplies that come in contact with the skin should be sterilized prior to use, this includes tweezers, scissors, nail files, nail clippers and any other tool that can potentially cause infection.

Autoclaves are also used to purify bottles and other containers used to store products. This is important because it prevents the spread of bacteria and other microorganisms that could contaminate products. There are several different types of autoclaves available on the market, but the most popular is the gas type. They use propane or natural gas to generate steam. The advantage of using them is that they are less expensive than electric models. They are also more portable, which makes them a good choice for salons and spas that do not have a lot of space.

Instructions for use

When using an autoclave, it is important to carefully follow the manufacturer’s instructions. These include:

- The cycle must be long enough to kill all bacteria and other microorganisms.

- If the cycle is too short, it will not be effective.

- If the cycle is too long, it may damage tools or supplies.

- It is also important to make sure it is set to the correct pressure. If the pressure is too high, it can damage tools or supplies.

- If the pressure is too low, it will not be effective. The pressure should be checked before each use, and the autoclave should be turned off if the pressure is not correct.

- It should be allowed to cool before opening. This helps prevent the escape of steam, which could scald the skin.

- The equipment should be cleaned after each use. This helps to eliminate any bacteria or other microorganisms that may have been left behind.

Thus, the equipment is a disinfection unit that uses gas as the sterilizing agent. The gas can be propane, butane or natural gas.

Its wide range of sizes and capacities make the autoclave the best choice for a wide range of applications. The conical cylinder and sterilization chamber allow the gas to circulate freely around the objects to be sterilized, guaranteeing a complete process.

Kalstein Gas Autoclave

We, at Kalstein, offer our customers the best equipment with the best technology for recording the methods of use of Autoclaves. They belong to the YR series and provide an excellent use, they are simple and easy to use. They are made of stainless steel, giving an elegant touch to the place. It has a voltage of 220-240v/ 50Hz, 110-120v/60Hz and power of 1500W. If you want to see more of our equipment, check our catalog HERE.